CALL: 1-855-WE-HEAT-IT

Vacuum Heat Treating Services

Quality You Can Rely On

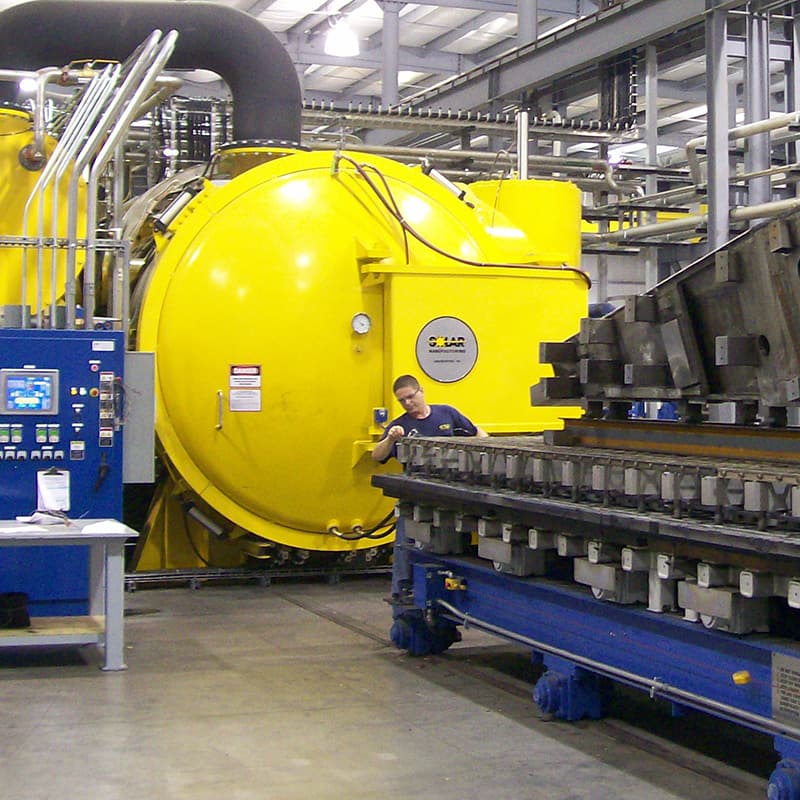

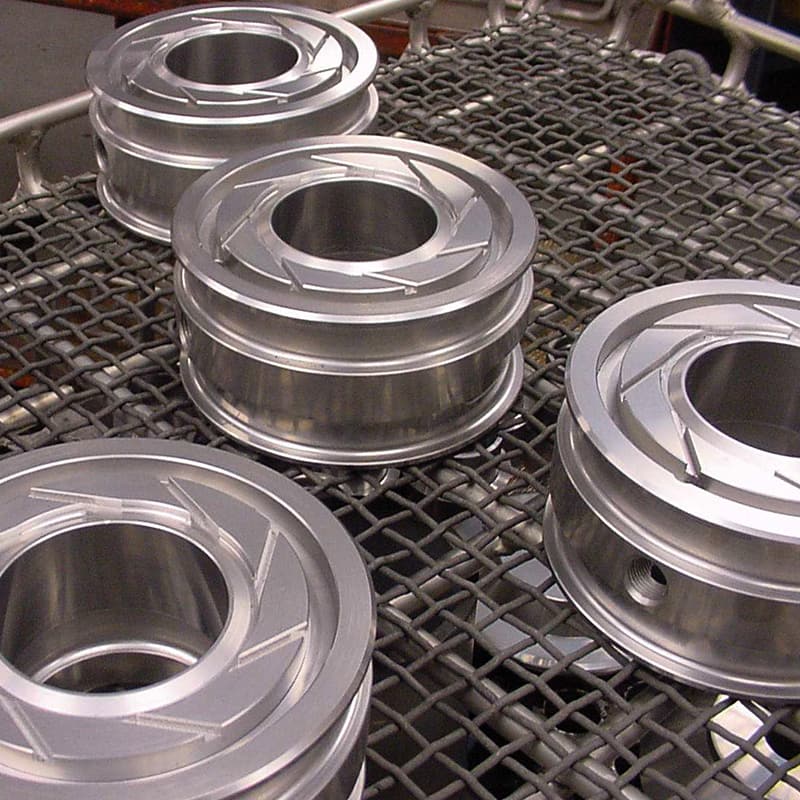

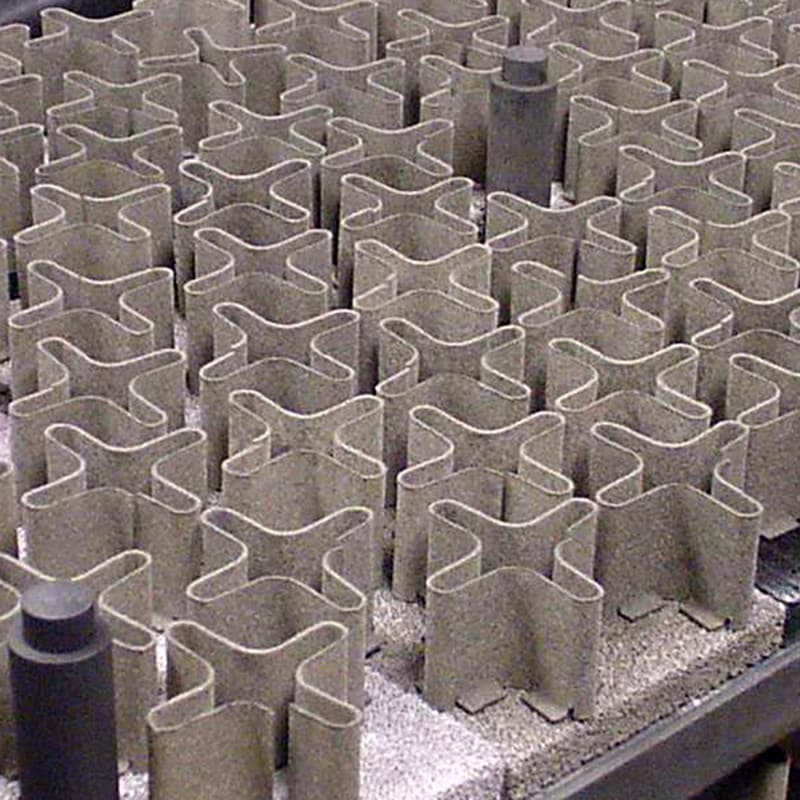

Add value to your parts by leveraging Solar Atmospheres’ vacuum heat treating services with our unmatched technical expertise, quality and world-class equipment. With our extensive range of processes, and with over 70 furnaces for vacuum heat treating & brazing services, ranging from lab-size research and development furnaces to the largest commercial vacuum furnace (48 feet long, 150,000 pound capacity), you will realize innovative and efficient solutions. From bearings to blades and beyond, partner with Solar Atmospheres for results that exceed your expectations. Get reliable turnaround with responsive service, and coast-to-coast, 24/7 operations.

Furnace Capabilities List

- Aircraft parts and equipment

- Power Generation blades and components

- Medical devices

- Implants

- Tooling

- Gears

- Braze assemblies

- Plate

- Forgings

- Bar

- Ingots

- Weldments

- Structural Components

- Castings

- Sheet

- Tube and pipe

. . . and more

Materials

- Alloy Steels

- Titanium

- Stainless Steel

- Precipitation Hardening Stainless Steel (PH)

- Inconel

- Nickel Based Alloys

- Tantalum

- Nitinol

- Hiperco 50/50A

- AerMet® 100

- Tungsten

- Zirconium

- Tool Steel

- High Speed Tool Steels

- Hot Working Tool Steels

- Copper

- Brass

. . . and more

Vacuum Heat Treating Services

Select a heat treating service below to find out more. For clarification of terms, please visit our glossary.